- Home

- Technology & Solutions

- Brittle Materials

Brittle Materials

Brittle materials such as silicon, silicon carbide, aluminum nitride, alumina, and some semiconductor materials are prone to cracks, fractures, or thermal stress damage during laser machining due to their unique physical and chemical properties. This presents significant challenges in machining quality and efficiency.

Solutions for precision cutting and drilling of brittle materials are available

Water-Jet Guided Laser

- Cooling and scouring effects of water flow reduce heat impact, recast layers, and eliminate micro-cracks

- High-energy laser coupled with water jet enables non-contact, high-precision machining

Rotary Cutting and Drilling

- Ultrashort pulse machining virtually eliminates heat conduction

- Producing neat hole walls without burrs, recast layers, micro-cracks, or metallurgical defects

- The high single-pulse energy enables exceptional machining accuracy and precision on almost any solid material

- It is ideal for both standard and personalized solutions for comprehensive product portfolio including brittle material workpieces

Brittle Material Machining

Video List

4 Videos

Application cases

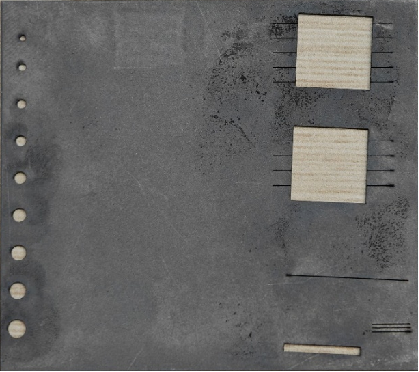

Aluminum Nitride

- Extremely low thermal impact, can accurately cut hard and brittle materials.

- Stable and efficient machining.

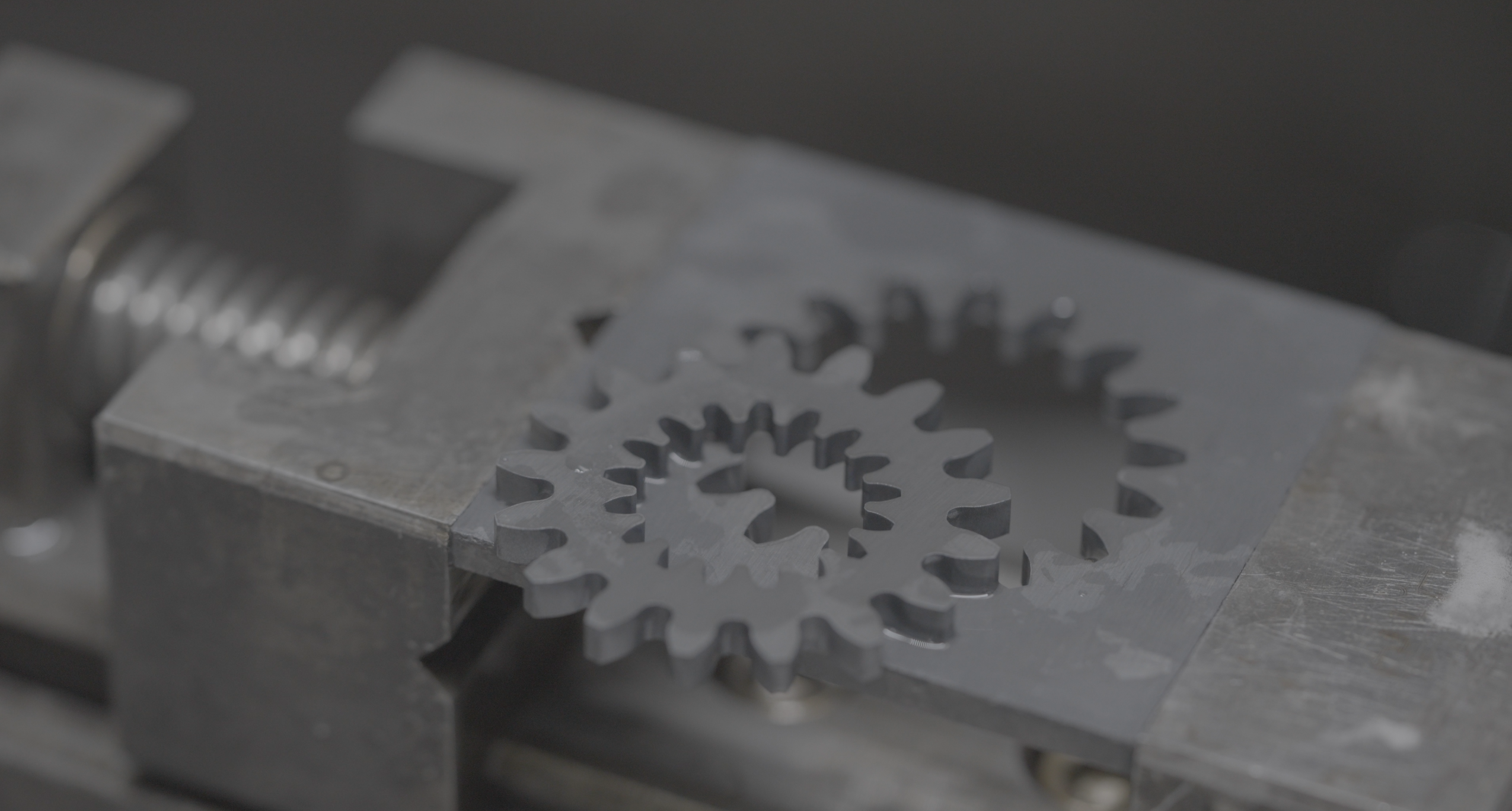

SiC

- Precision shape cutting.

- Smooth cut surface, no cracks.

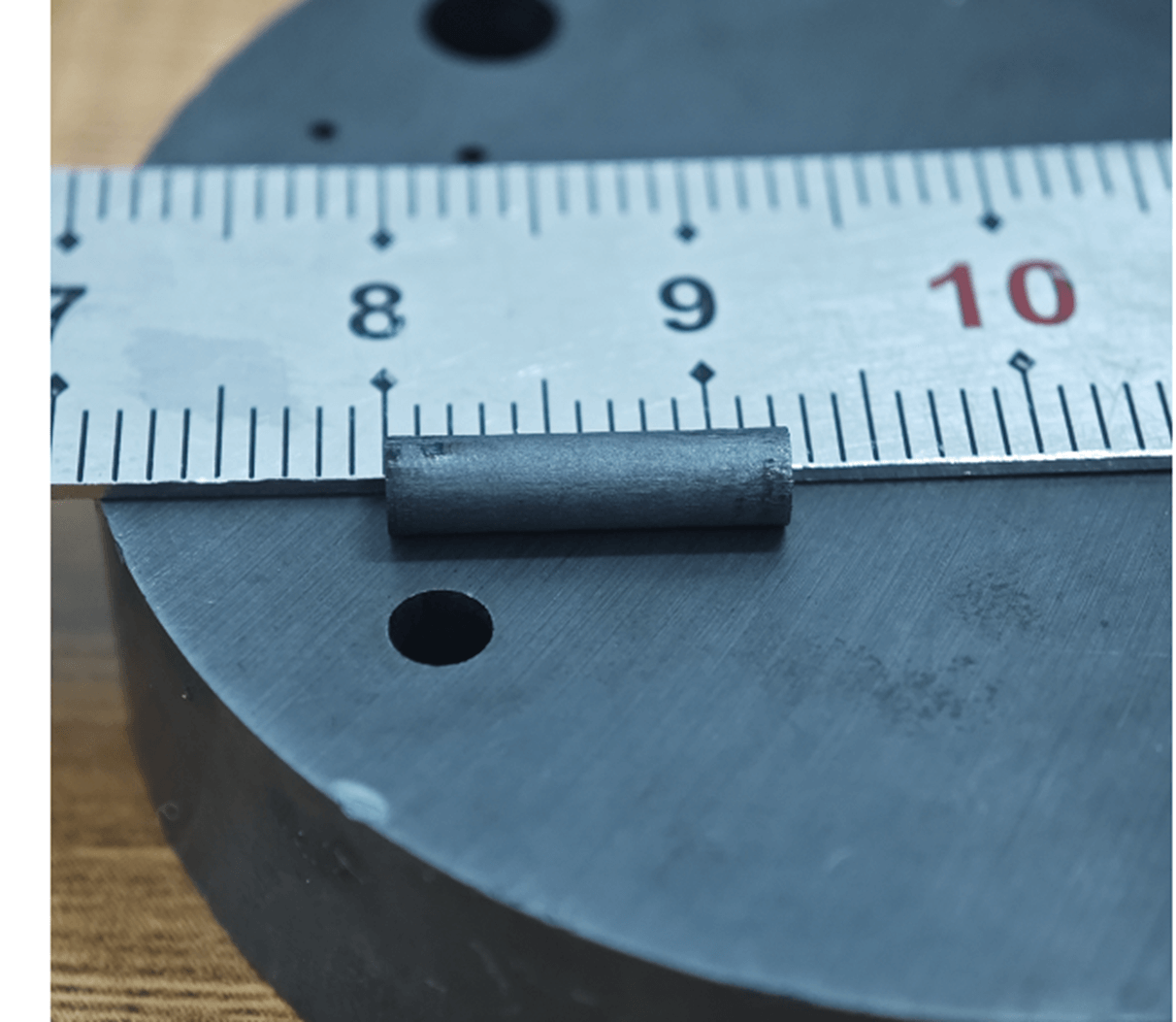

Drilling

- Machining without taper, smooth cut surface without cracks.

- Precision micro-hole machining.

Titanium Alloy

- Machining without taper.

- Machining of micro holes in various materials.

Machine Tools